Conveyors

Gravity Idler Roller Conveyor

- Length: More than 1500 mm

- Roller Material: Mild Steel

- Roller Diameter: 35-55 mm

- Country of Origin: Made in India

- Minimum Order Quantity: 5 Meter

At VISION9MB Engineering International Pvt. Ltd., we bring unmatched expertise in designing, manufacturing, and installing Gravity Idler Roller Conveyors tailored to specific operational needs. Leveraging our deep understanding of material flow dynamics and ergonomic handling, we engineer conveyors that ensure smooth, reliable, and safe movement of goods. Our capabilities include:

- Custom Design: Configurations optimized for load capacity, layout constraints, and process flow.

- Precision Manufacturing: Use of high-quality materials, advanced fabrication techniques, and strict quality control.

- Seamless Installation & Commissioning: On-site integration with existing material handling systems, ensuring minimal downtime.

- End-to-End Solutions: From concept to commissioning, backed by prompt after-sales service.

Ball Transfer Unit

- Material: Stainless Steel

- Ball Diameter: 25mm to 50 mm

- Country of Origin: Made in India

- Minimum Order Quantity: 5 Piece

At VISION9MB Engineering International Pvt. Ltd., we specialize in designing, manufacturing, and installing Ball Transfer Unit systems tailored to diverse industrial applications. Our expertise ensures optimal load distribution, long service life, and seamless integration with existing conveyor lines or workstations. Our capabilities include:

- Custom Design Solutions: Configurations suited for specific load capacities, table sizes, and process requirements.

- High-Precision Manufacturing: Use of durable materials and precision engineering for smooth and reliable performance.

- Versatile Integration: Standalone ball tables, embedded units, or hybrid conveyor-ball transfer systems.

- On-Site Installation & Commissioning: Fast, efficient setup with minimal disruption to ongoing operations.

- Comprehensive Support: Maintenance, spares, and system optimization for sustained performance.

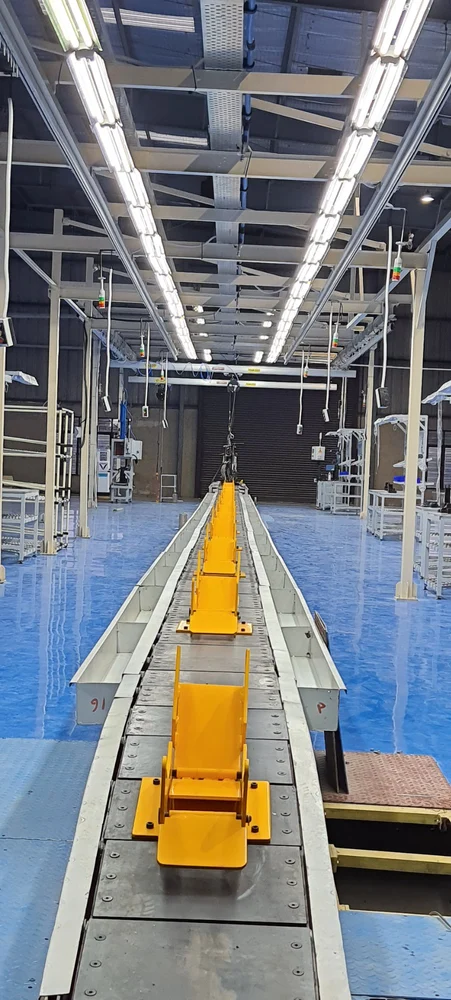

Slat Conveyor System

- Material: Stainless Steel (SS)

- Chain Type: Slat

- Usage/Application: Material Handling

- Capacity: 50-100 kg per feet

- Belt Width: 0-10 inch

- Operating Speed: 1-2 m/s

- Power: 3 Phase Power Supply

- Length: 20-40 feet

- Country of Origin: Made in India

- Minimum Order Quantity: 2 Piece

At VISION9MB Engineering International Pvt. Ltd., we specialize in designing, manufacturing, and installing Slat Conveyor Systems tailored to meet the specific requirements of each client. Our solutions combine mechanical strength with smooth, reliable operation, ensuring long-term performance even in the most demanding environments. Our capabilities include:

- Custom-Built Designs: Slat widths, lengths, and chain configurations engineered for load type, weight, and process needs.

- Material Flexibility: Steel, stainless steel, or engineered plastic slats to suit environmental and operational conditions.

- Precision Fabrication: Robust frame construction, high-quality chain assemblies, and accurate alignment for optimal performance.

- Integration Expertise: Seamless incorporation with assembly stations, robotic systems, or packaging lines.

- Complete Lifecycle Support: Installation, commissioning, preventive maintenance, and timely spares supply.